Against the backdrop of rapid development in 3D printing technology, the mold manufacturing industry has undergone unprecedented changes. This cutting-edge technology, with its unique advantages such as improving production efficiency and simplifying manufacturing processes, is gradually becoming an important tool for mold manufacturing. However, despite the significant achievements of 3D printing technology in other fields, purchasing 3D printing equipment alone is not enough to do well in mold 3D printing. So why is mold 3D printing difficult?

The demand for molds has high requirements for wear resistance, corrosion resistance, thermal conductivity, polishing, breathability, cooling, etc. Traditional mold manufacturing has mature materials and processing methods, while 3D printing can achieve the manufacturing of complex structures, it is often difficult to fully reach the level of traditional processes in terms of accuracy and material performance. Especially the limited selection range of steel materials for 3D printing molds poses a challenge to the final mold quality.

In addition, after 3D printing is completed, the mold usually needs to undergo a series of post-processing processes, such as heat treatment, surface treatment, etc., to meet the final usage requirements. Developing post-processing techniques suitable for 3D printed workpieces also brings additional technical challenges to enterprises. For example, how to avoid deformation and cracking of 3D printed workpieces through post-processing; Surface treatment of 3D printed workpieces, etc.

Therefore, the successful application of mold 3D printing not only requires advanced equipment and materials, but also rich technical experience and professional knowledge. For example, how to choose appropriate printing parameters, optimize printing processes, and handle problems that arise during the printing process all require technical personnel to have profound professional knowledge and practical experience.

In summary, the main reason why 3D printing of molds is difficult is that it faces strict demands from the mold industry, which places high demands on equipment, materials, printing processes, post-processing techniques, and other aspects. However, with the continuous advancement of technology and the accumulation of experience, the challenges of mold 3D printing are gradually being solved.

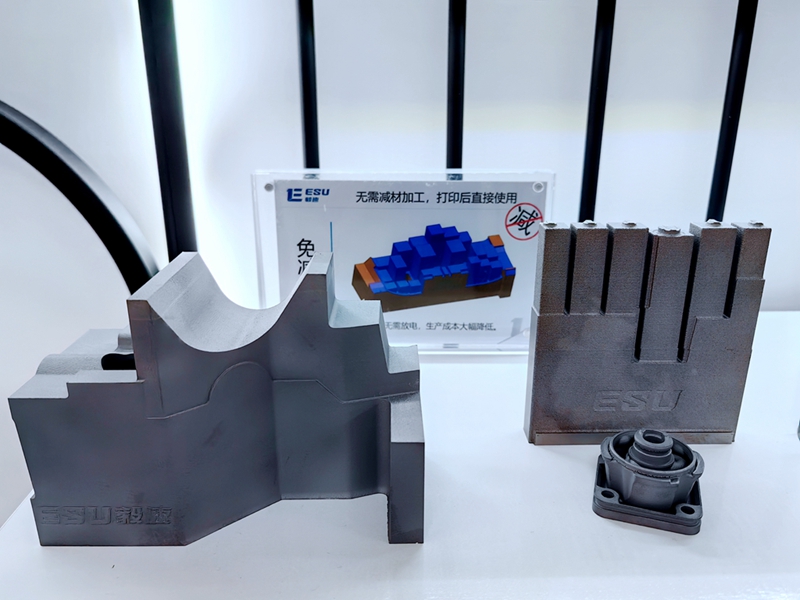

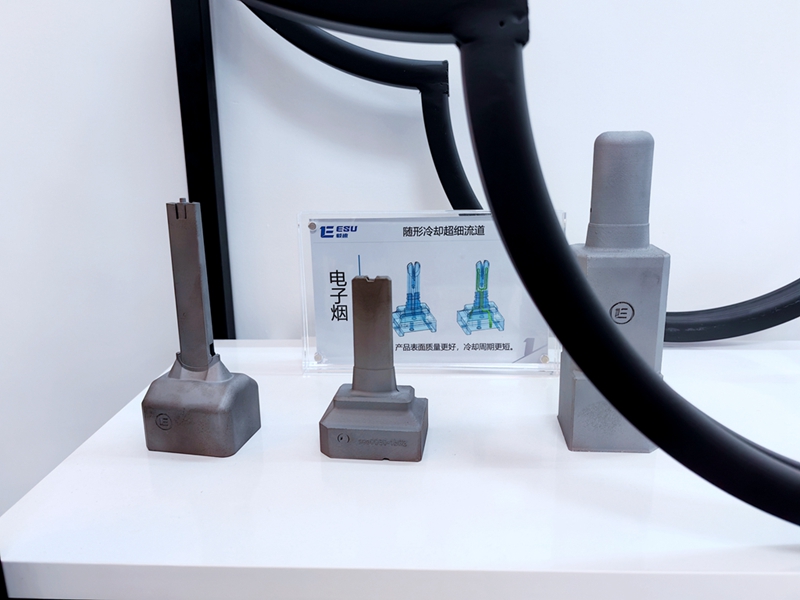

With the continuous improvement of printing accuracy and efficiency, 3D printing is reshaping the pattern of mold manufacturing. In some fields such as shoe molds and tire molds, 3D printing has opened up large-scale applications. Yisu has launched a one-stop 3D printing solution for molds, tailored to meet the development needs of enterprises based on their characteristics. The solution covers site planning, 3D printing equipment and auxiliary equipment configuration, metal powder configuration, process packages, supporting software, engineer and operator training, long-term operation and maintenance, etc. Helping mold companies easily achieve transformation and upgrading, opening a new chapter in intelligent manufacturing.