On November 6, the "AI+Intelligent Manufacturing Molding Industry Ecological Strategy Exchange and Dialogue for Promoting Change and Winning the Future in 2024" was held at Sun Island Tourist Resort in Qingpu, Shanghai, co-hosted by the National Molding Ecological Alliance, Shanghai Xiechuang Intelligent Equipment Technology Research Institute, Shanghai Kechuang Vocational and Technical College, and Shanghai Second Polytechnic University Intelligent Manufacturing College. Shanghai ESU Laser Technology Co., Ltd. Chairman Zhang Zhanbo was invited to attend the event and delivered a keynote speech on the current status and future trends of mold 3D printing at the event.

The chairman of Shanghai ESU, Zhang Zhanbo, explains the current status and future trends of mold 3D printing technology.

It is reported that over 100 CEOs, general managers, and chairmen from brand automobile factories, robot enterprises, intelligent manufacturing enterprises, plastic enterprises, plastic mold industry enterprises, stamping mold enterprises, injection molding machine enterprises, numerical control equipment enterprises, numerical control processing enterprises, material enterprises, mold standard parts enterprises, mold material enterprises, and higher education institutions from all over the country participated in the event.

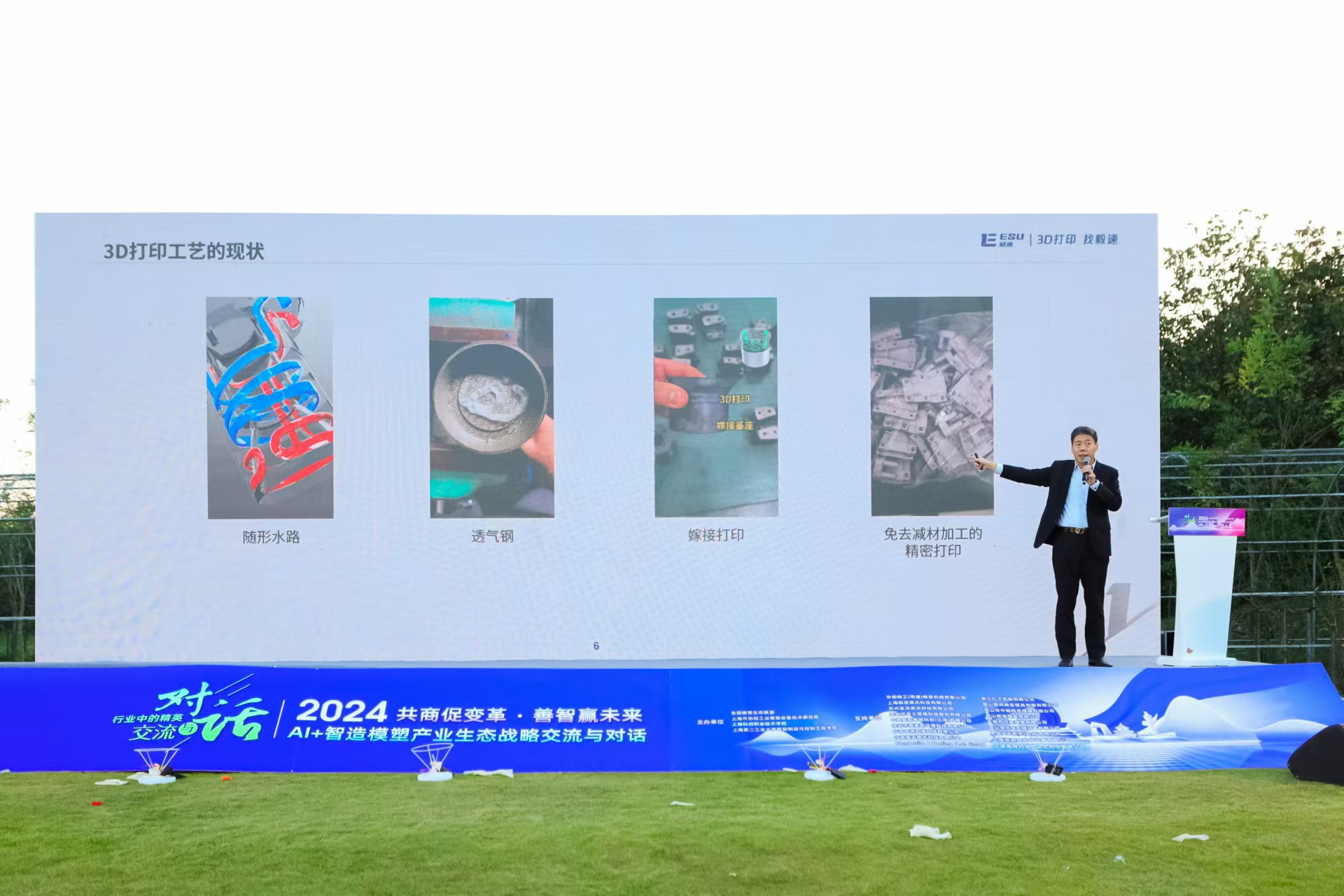

The chairman of Shanghai ESU, Zhang Zhanbo, explains the current status and future trends of mold 3D printing technology.

3D printing has gained significant momentum in the molding industry due to its high design freedom and short production cycle, which can significantly enhance mold performance. In recent years, 3D printing technologies such as conformal cooling channels and conformal ventilation steel have been widely applied in injection molds, die casting molds, foam molds, blow molds, shoe molds, paper molds, rubber molds, tire molds, and silicone molds. In his speech, Zhang Zhanbo, chairman of ESU, detailed the changes brought about by 3D printing to the molding industry and provided a deep analysis and trend forecast of the three core elements, equipment, materials, and processes, as well as the industry's future.

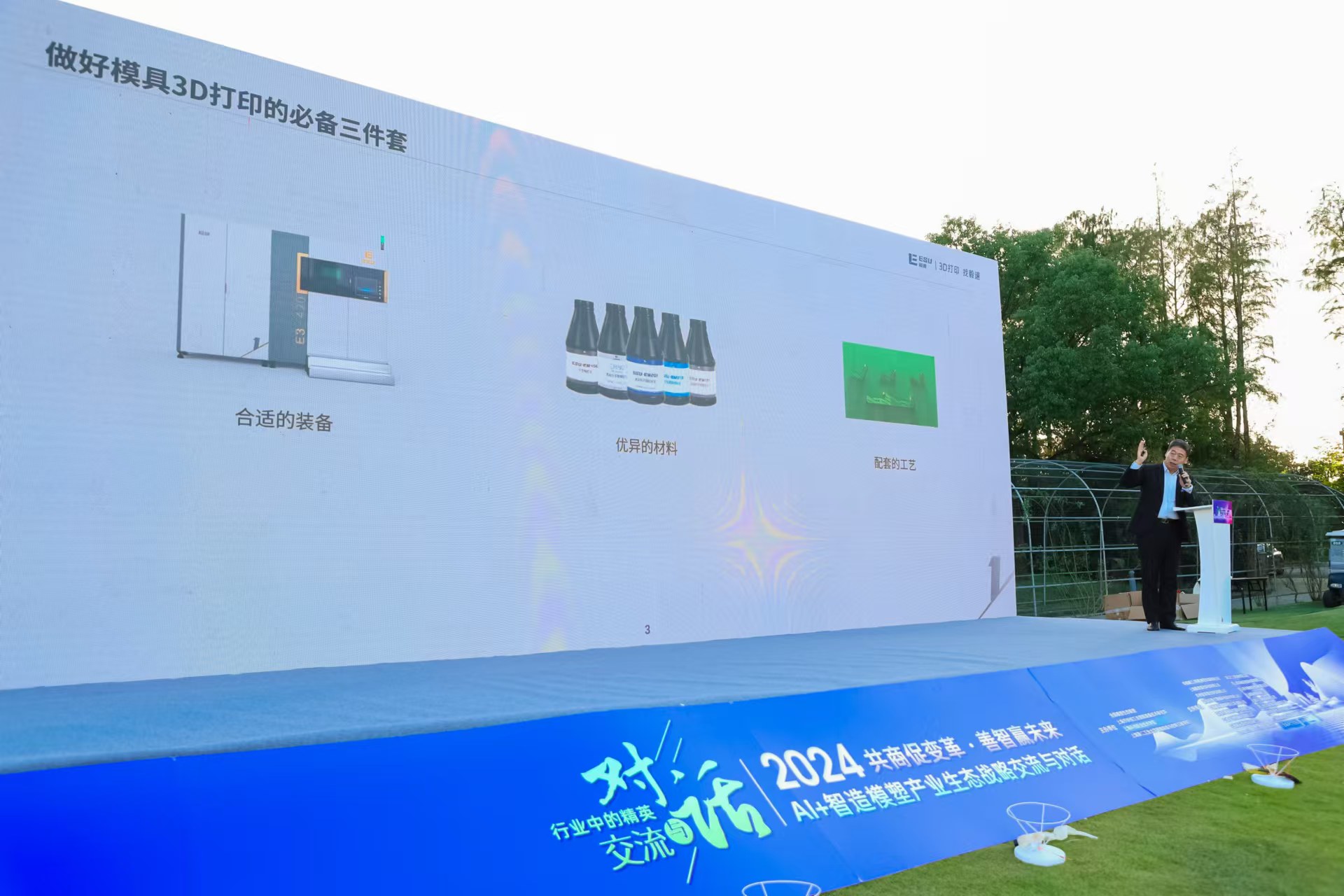

The chairman of Shanghai ESU, Zhang Zhanbo, explains the current status and future trends of mold 3D printing technology.

Zhang Zhanbo pointed out that traditional mold processing starts with material preparation, with a long production process, requiring a variety of equipment, complex operation, and relatively high personnel requirements. With the continuous improvement of 3D printing in printing accuracy and efficiency, the manufacturing process can be reduced to two steps of machine printing and post-processing by 3D printing. He stressed that 3D printing will definitely revolutionize mold manufacturing in the future and has the potential to fully replace subtractive manufacturing. At the same time, he called on the industry peers to recognize the trend and embrace new technologies, actively embrace changes and keep up with the times, which will be the right choice for the long-term development of the enterprise.

The chairman of Shanghai ESU, Zhang Zhanbo, explains the current status and future trends of mold 3D printing technology.

Shanghai ESU, as a technology-driven enterprise with a solid foundation in the mold industry and many years of practical experience in metal 3D printing, has now established a six-in-one business module, including 3D printing equipment, materials, processes, services, additive-subtractive integration, and assisting customers in setting up factories. This has completed the closed-loop of 3D printing technology and formed a strategic pattern of healthy and ecological development. Based on its accumulated industry experience, Shanghai ESU can help mold enterprises successfully set up and operate 3D printing departments, thus achieving the integration and application of the advantages of additive and subtractive manufacturing technologies, accelerating the transformation of the mold industry towards additive manufacturing.