3D printing is leading the mold manufacturing industry through a technological revolution, with the widespread application of flexible waterways being particularly noteworthy. This technology has brought disruptive innovation value to the field of mold manufacturing with its significant advantages of improving cooling efficiency, optimizing product design, and reducing costs.

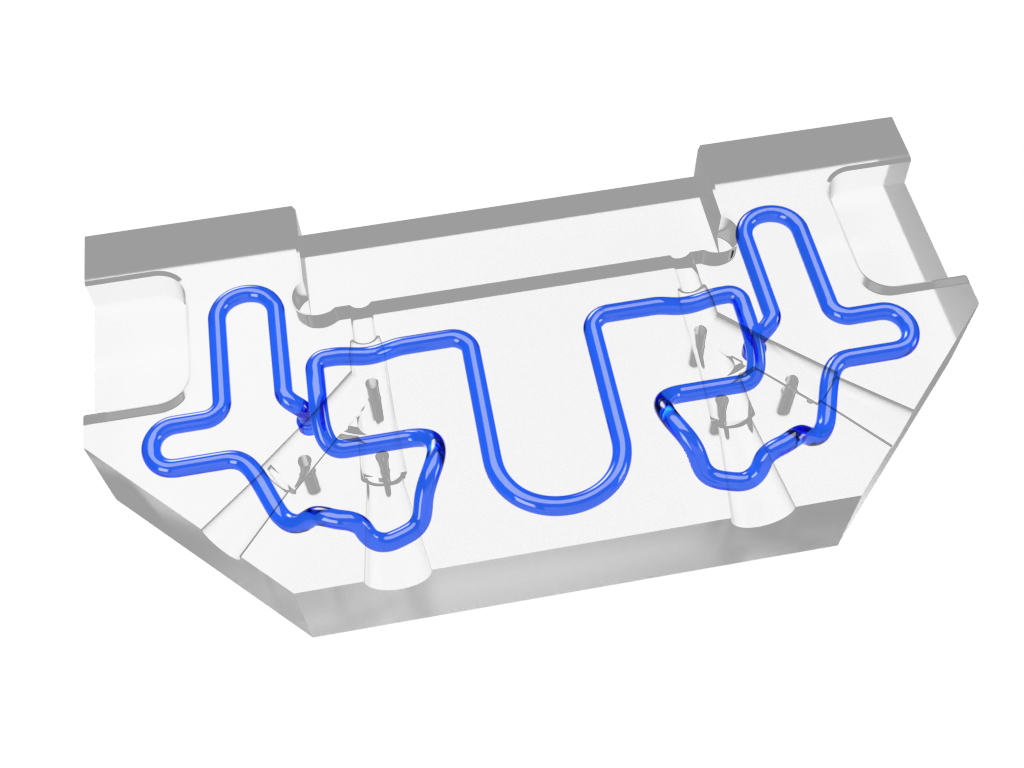

Conventional waterways are usually straight and far from the surface of the mold cavity, making it difficult to achieve precise temperature control. The problems of deformation, burning, and discoloration in injection molding are often caused by uneven mold temperature. As a customized cooling system based on the product contour, the flexible waterway can be evenly distributed to achieve precise and efficient temperature control.

Compared to traditional linear waterways, the advantages of flexible waterways are reflected in the following aspects: firstly, this design optimizes the product cooling process, effectively reduces injection molding defects, improves overall product quality and performance, and thereby increases product added value; Secondly, by closely fitting the design of the product shape, the cooling efficiency is significantly improved, the mold cooling time is shortened, the production efficiency is improved, and the overall manufacturing cost of the product is reduced.

Random waterway is often achieved through 3D printing selective laser melting (SLM) technology, which cannot be manufactured through traditional subtractive processing. At present, the application of 3D printed flexible waterways in mold manufacturing has become increasingly widespread, covering multiple industries such as 3C products, medical devices, packaging materials, automotive parts, and household appliances. For example, many products such as game controllers, Bluetooth earphones, cosmetics packaging, home appliance casings, and automobiles have adopted 3D printed flexible waterways. The widespread application of this technology not only promotes the transformation and upgrading of the mold manufacturing industry, but also provides strong support for the efficient development of related industries.