On June 4, 2025, the "2025 China Yangtze River Delta Mold Industry Summit Forum and Shanghai Mold Technology Association 55th Anniversary Celebration" was grandly held at the Shanghai Huamingdu Hotel. As a co organizer of this event, Shanghai ESU Laser Technology Co., Ltd. (hereinafter referred to as "ESU Laser") made a brilliant appearance with cutting-edge metal 3D printing and overall solutions. ESU Laser COO Wang Lijun delivered a keynote speech on "AI Empowerment and Additive Empowerment - Metal 3D Printing Driven Mold Manufacturing Upgrade", deeply analyzing the innovative value of the integration of AI and additive manufacturing technology in the mold industry, which has attracted widespread attention in the industry.

On site of the Yangtze River Delta Mold and Plastic Industry Summit Forum

Technical report highlights frequently, AI and additive manufacturing dual wheel drive

In the technical report section, Wang Lijun, COO of ESU Laser, shared the innovative application of metal 3D printing technology in the field of mold manufacturing around the dual themes of "AI empowerment" and "additive empowerment"

· AI empowers device performance optimization:Using deep learning algorithms to achieve online detection and feedback control during the printing process, improving device printing consistency and stability, adaptively adjusting process parameters, optimizing the distribution of the melt pool thermal field, and enhancing printing accuracy.

· Additive manufacturing breaks through traditional limitations:Taking the "electronic cigarette mold insert" as an example, the traditional mold cooling cycle is about 14 seconds, which can be shortened to 7 seconds by using 3D printed conformal water channels, significantly improving injection molding efficiency and reducing product deformation rate.

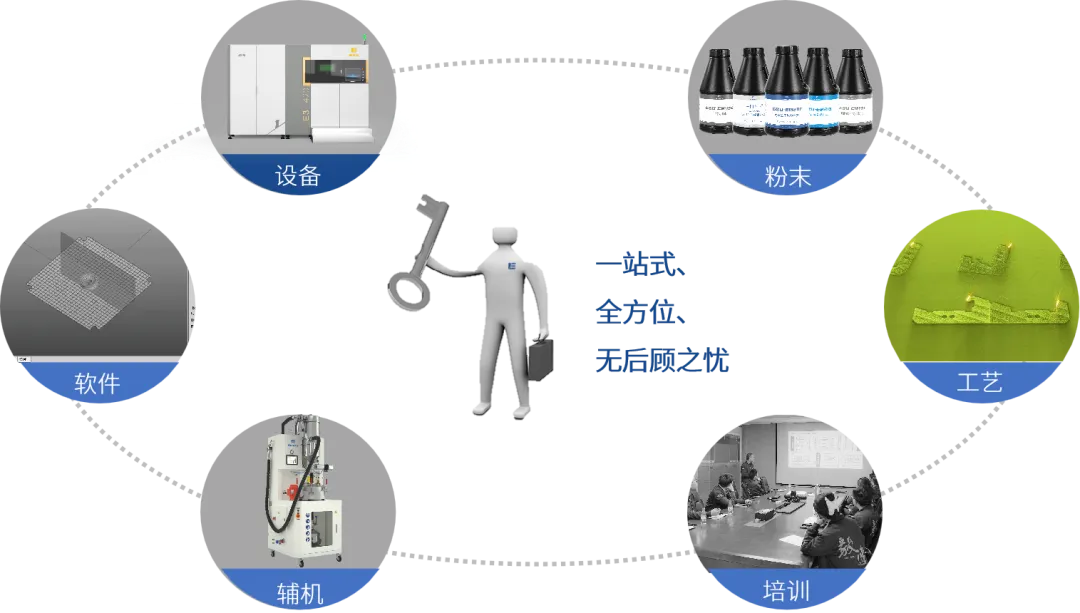

· Six in One Collaborative Drive:ESU Laser has established a six in one main business, providing over 200000 application cases for more than 2000 well-known enterprises worldwide, laying a leading position in the field of mold 3D printing!

· ① Printing equipment —— Multi laser metal 3D printers E3-420 and E3-520 based on L-PBF technology

· ② Printing materials —— ESU-EM400 high polished mold steel powder, ESU-EM300 high wear-resistant mold steel powder, ESU-EM201 high thermal conductivity mold steel powder, ESU-EM213 hot work mold steel powder, ESU-EM456 stainless steel powder

· ③ Printing process —— 3D printing of breathable steel, 3D printing of flexible waterways, grafting 3D printing, 3D printing without subtractive processing, etc

· ④ Printing service —— Covering injection molds, die-casting molds, paper molds, blow molds, rubber molds, silicone molds, shoe molds, tire molds, foam molds, knife molds, other metal 3D printed parts, etc

· ⑤ Increase/decrease synergy ——3D printing post-processing, precision machining, grafting base processing, etc

· ⑥ Overall solution —— After conducting comprehensive and authentic research to understand the needs and pain points of users, the professional team of ESU Laser conducts a feasibility analysis of the overall solution for users, including configuring mold 3D printing specialized equipment, specialized materials, specialized processes, supporting auxiliary equipment, site planning, personnel training, and finally providing long-term operation and maintenance services.

Mold 3D Printing - Overall Solution

Wang Lijun emphasized that metal 3D printing is not only an innovation in manufacturing technology, but also an upgrade in industrial thinking from 'subtractive manufacturing' to 'additive manufacturing'. The deep integration of AI technology and 3D printing by ESU Laser is driving the transformation of mold manufacturing towards' personalization, high efficiency, and low energy consumption '

ESU Laser COO Wang Lijun delivers a speech

Showcasing brand strength and empowering industrial innovation and development

As an important participant in the 55th anniversary celebration of the Shanghai Mold Technology Association, the technical strength and industry contribution of ESU Laser have been widely recognized. The on-site display of 3D printed breathable steel molds, conformal water injection molds and other physical cases by the company attracted many attendees to stop and exchange ideas. The technical director of a certain attending enterprise said, "The solution of ESU Laser has effectively solved the efficiency and accuracy problems in our complex mold manufacturing, especially in the application of new energy vehicle battery shell molds, and its technical advantages are very prominent.

At this forum, ESU Laser not only demonstrated its leading position in the field of metal 3D printing through technology sharing, but also further solidified its brand positioning as a "leader in mold 3D printing" through deep interaction with industry organizations, universities, and enterprises. In the future, the company will continue to deepen the integration of AI and additive manufacturing technology, contributing more innovative strength to the high-quality development of the molding industry in the Yangtze River Delta and even the mold industry in China.