On June 21, 2025, "Dawan District Mold Industry Innovation Conference and Shenzhen Mold Technology Association annual meeting" was grandly held in Shenzhen. Wanglijun, the director and deputy general manager of Shanghai ESU Laser Technology Co., Ltd. (hereinafter referred to as "ESU laser"), delivered a powerful speech entitled "Ai intelligence, additive energy - upgrading of metal 3D printing driven mold manufacturing". With a set of shocking data, it revealed the deep reconstruction of 3D printing technology on mold manufacturing industry: a set of smoke bomb mold inserts (8 holes in a mold), the cooling time was reduced from 14 seconds to 7 seconds, and the monthly production capacity was increased by 138240 pieces. ——This is just the epitome of ESU 200000+application case.

ESU laser Mr. Wang Lijun's speech

ESU laser Mr. Wang Lijun's speech

Mold 3D printing overall solution provider

As one of the few domestic 3D printing service providers that "focus on mold tracks", ESU laser has built full scene solutions covering ten mold types: injection mold 3D printing, die casting mold 3D printing, paper plastic mold 3D printing, blow molding mold 3D printing, rubber mold 3D printing, silicone mold 3D printing, shoe mold 3D printing, tire mold 3D printing, foam mold 3D printing, and knife mold 3D printing. The selected cases shared in the speech revealed that 3D printing is changing from 'optional' to 'required'.

On site exhibits

On site exhibits

Efficiency explosion point of electronic cigarette industry

In his speech, wanglijun disassembled the upgrading path of an electronic cigarette enterprise at the head: the size of the insert is small, and the diameter of the conformal waterway has reached the limit of 3~4mm in a limited space. There is a long section of thin iron at the head, so the conformal waterway cannot be designed, and the cooling effect is difficult to be improved qualitatively. With years of experience, ESU laser has designed a flat spiral waterway for it. In particular, it combines the esu-em201 high thermal conductivity mold steel powder developed by ESU laser (which has been authorized by Chinese and European invention patents) for printing to improve the overall thermal conductivity of the insert, so as to shorten the injection cooling time by 50%, reduce the molding cycle by 20%, and increase the production capacity by 138240 pieces per month. This one piece alone has added an annual output value of more than 710000 yuan for the enterprise.

Electronic cigarette mold insert

Schematic diagram of electronic cigarette products

Enlightenment from technology transfer of shoe mold manufacturing

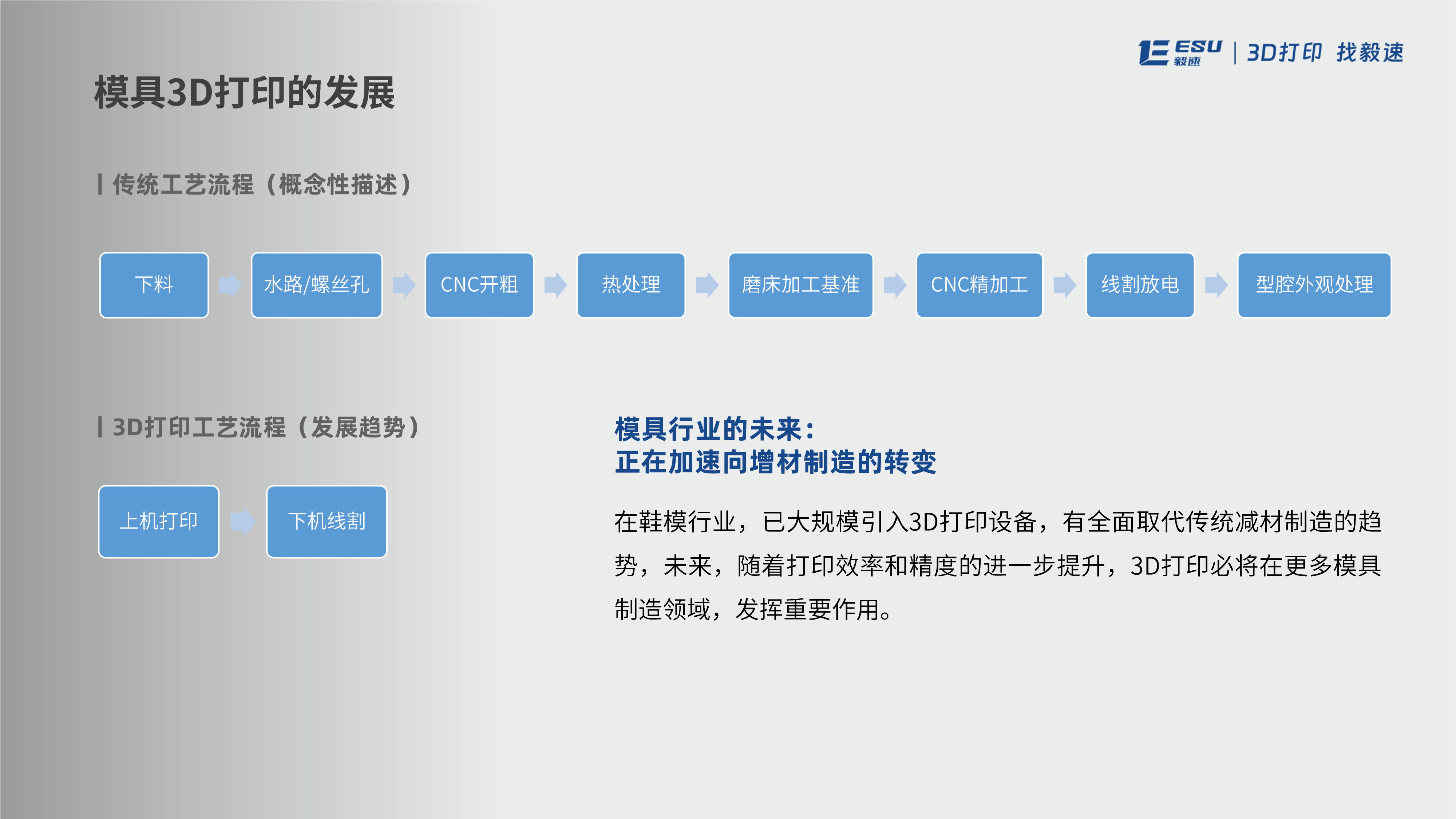

Wanglijun especially pointed out the reform of shoe mold industry: 3D printing equipment has been introduced on a large scale, which has the advantage of replacing traditional reduced material manufacturing. In the future, with the further improvement of printing efficiency and accuracy, 3D printing will play an important role in more mold manufacturing fields. 3D printing technology is adopted for mold manufacturing, which can ① rapidly cool the mold temperature and shorten the molding cycle; ② Solve the problem of die gas trap; ③ Shorten the processing procedure.

Wanglijun concluded: "the window period for molders to embrace 3D printing is closing - the early transformation will benefit the early ten years.". Let's witness the wave of 3D printing technology revolution together! ”

Development trend of 3D printing of die and mould