From June 4th to 7th, 2025, the China International Mold Technology and Equipment Exhibition (DMC 2025) was successfully held at the Shanghai New International Expo Center. Shanghai ESU Laser Technology Co., Ltd. (hereinafter referred to as "ESU Laser") made a stunning debut with its leading 3D printing technology and innovative application achievements, showcasing the diversified applications and overall solutions of 3D printing technology in the field of mold manufacturing to the global mold industry, becoming one of the highlights of the exhibition.

2025 DMC,The booth of ESU Laser is crowded with people

3D printing mold inserts attract viewers to stop and exchange ideas

At the "Additive Manufacturing and Mold Application Summit Forum" held concurrently with the exhibition, Wang Lijun, COO of ESU Laser, delivered a keynote speech titled "AI Empowering Additive Manufacturing - Metal 3D Printing Drives Mold Manufacturing Upgrade", sparking industry discussions.

ESU Laser COO Wang Lijun delivers a speech

3D printing technology empowers the mold industry, innovative applications attract attention

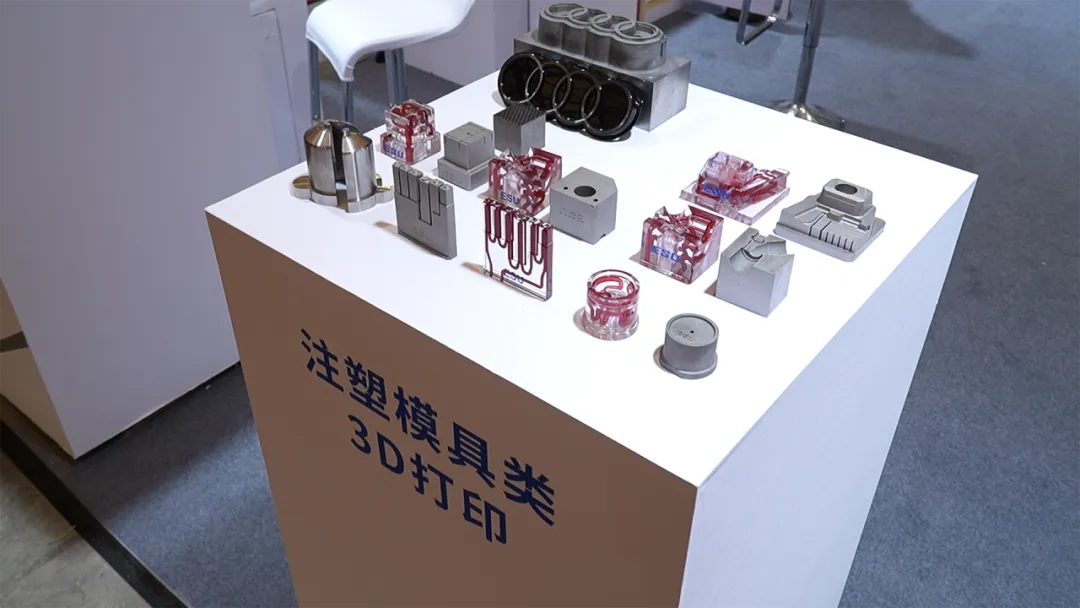

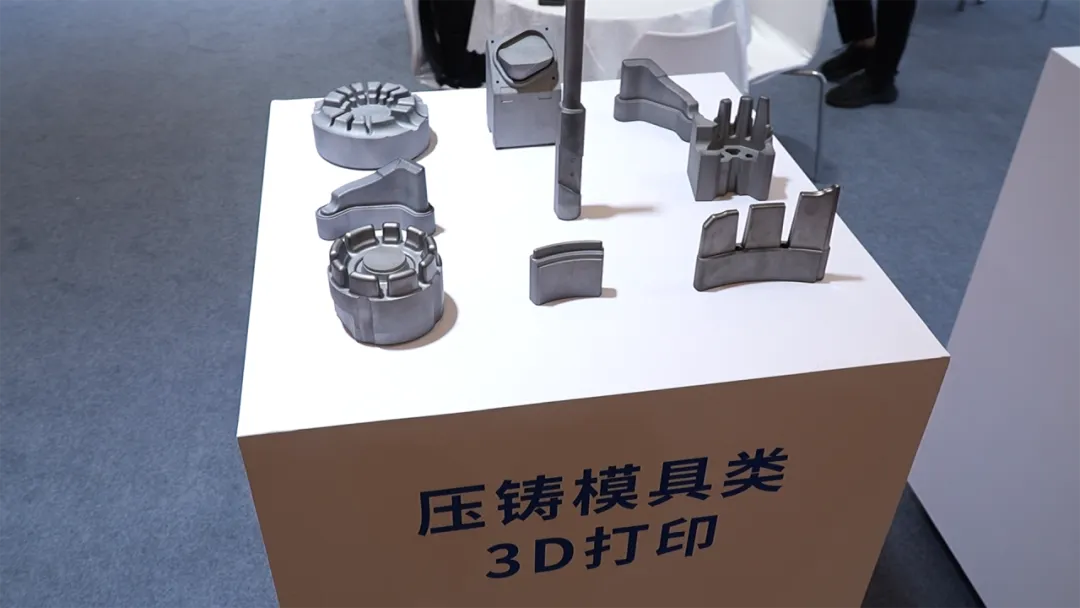

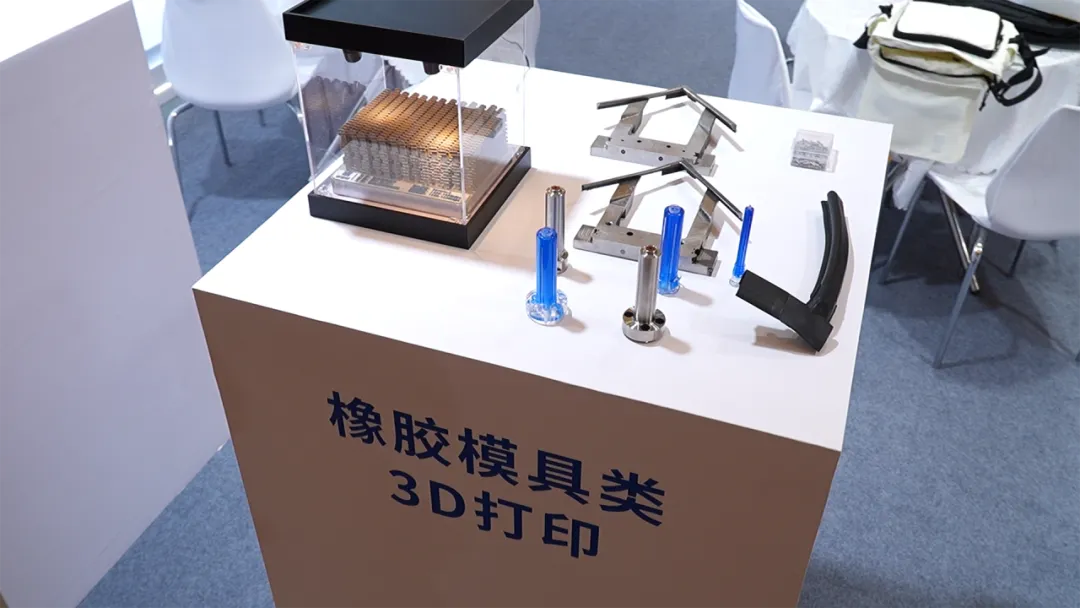

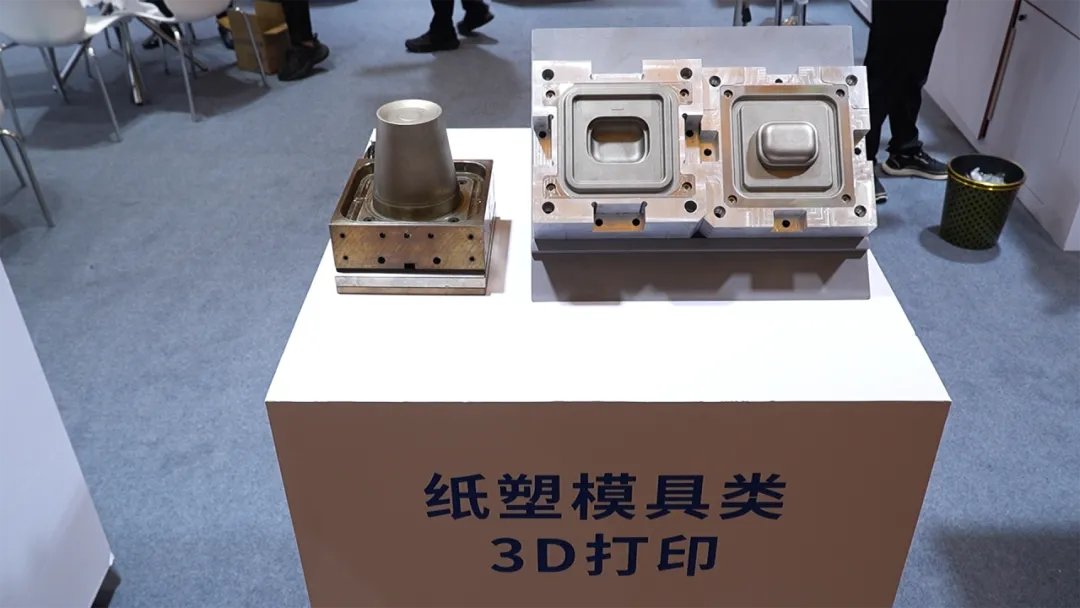

As a deep cultivator of additive manufacturing technology in the field of molds, ESU Laser showcased various 3D printed parts for the subdivision of molds, including breathable steel molds, injection molds, die-casting molds, fixtures, paper plastic molds, foam molds, rubber molds, hot runner 3D printed parts, etc., comprehensively presenting the significant advantages of 3D printing technology in complex structures, lightweight design, flexible waterway to solve mold temperature, breathable steel to solve mold trapped gas, rapid iteration, and cost optimization.

现场部分展品

From equipment to services, we provide a comprehensive solution for mold 3D printing

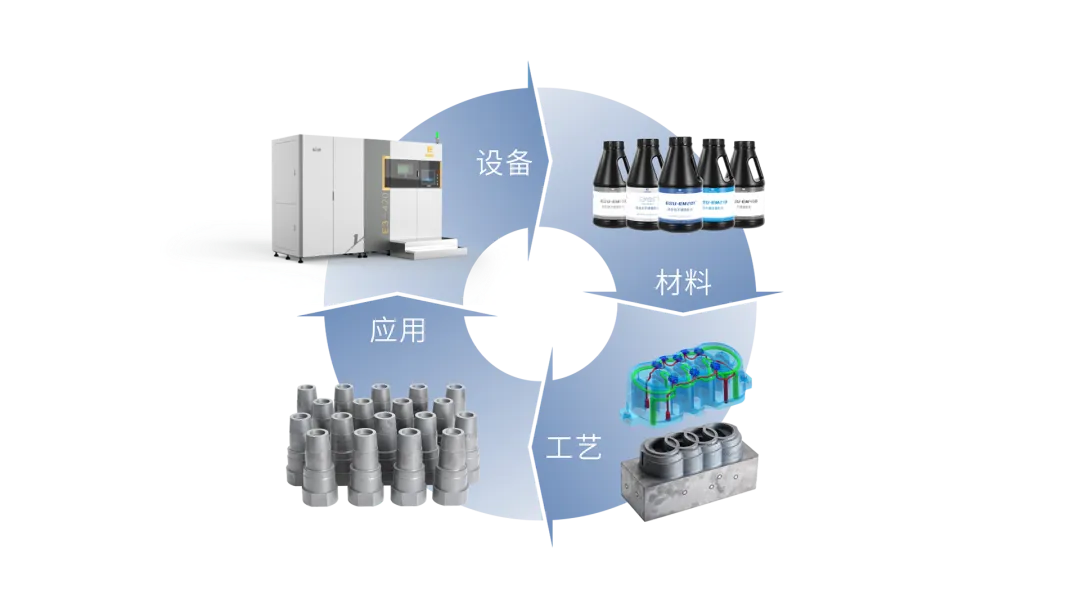

In addition to a wide range of printed materials, ESU Laser also demonstrates its full chain capability of "technology+equipment+service". Based on independently developed mold specific equipment, mold specific materials with invention patents, mold specific processes accumulated from over 200000 application cases, and a technical closed loop of mold application experience serving more than 2000 customers, ESU Laser is empowering Chinese mold enterprises with this complete set of "mold 3D printing overall solutions".

Equipment, materials, processes, and applications are mutually driven

After conducting comprehensive and authentic research to understand the needs and pain points of users, the professional team of ESU Laser conducts a feasibility analysis of the overall solution for users, including configuring mold 3D printing special equipment, special materials, special processes, supporting auxiliary equipment, site planning, personnel training, and finally providing long-term operation and maintenance services.

ESU Laser - Mold 3D Printing Integrated Solution

ESU Laser's COO Wang Lijun said, "ESU Laser is not only committed to providing customers with high-quality 3D printing services, but also hopes to help mold companies establish and operate 3D printing business units through independent equipment research and development and process innovation, and help the industry reduce costs and increase efficiency.

Technology drives the future, Yisu Laser continues to lead the way

Nowadays, the shoe mold industry has introduced 3D printing equipment on a large scale, and there is a trend to completely replace traditional subtractive manufacturing. In the future, with the further improvement of printing efficiency and accuracy, 3D printing will play an important role in more mold manufacturing fields.

ESU Laser, with its profound process accumulation and continuous R&D investment, has successfully applied 3D printing technology to mold manufacturing in multiple fields such as automotive, electronics, medical, and consumer goods. It helps customers quickly cool mold temperature, shorten molding cycles, solve mold trapping, and shorten processing steps.

In the future, ESU Laser will continue to use innovation as its engine to promote the large-scale application of 3D printing technology in the mold industry and accelerate the world's transition to additive manufacturing!