On May 28, 2025, Shanghai ESU Laser Technology Co., Ltd. (hereinafter referred to as "ESU Laser") held a "Mold 3D Printing Technology Exchange Conference" in Ninghai County, Zhejiang Province. This conference attracted numerous representatives from mold companies to discuss the application prospects of 3D printing technology in mold manufacturing and the importance of overall solutions.

Group photo of technical exchange meeting

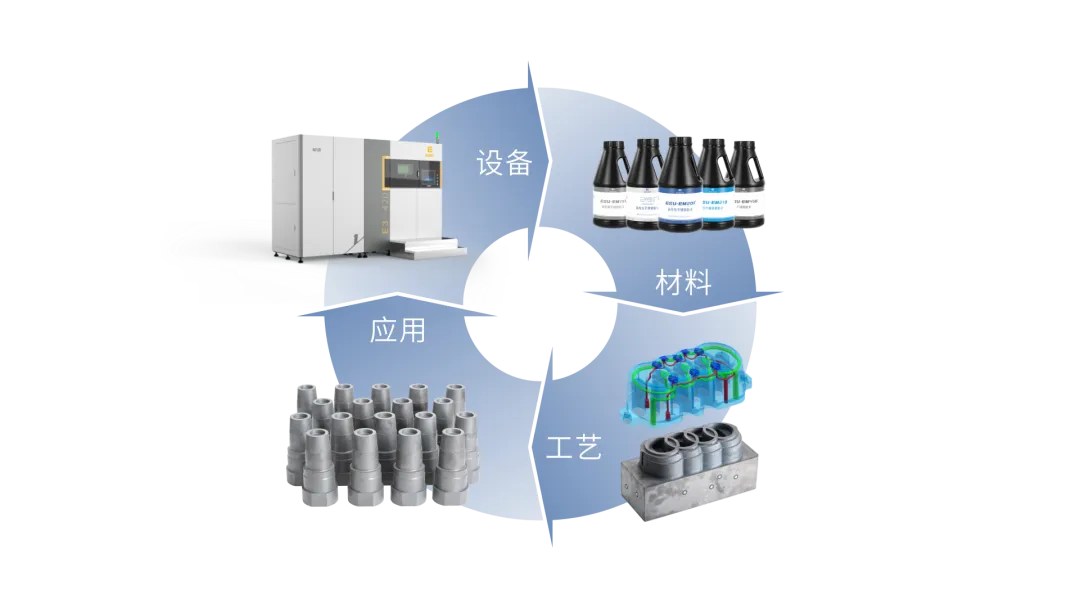

With the deepening of Industry 4.0, 3D printing technology has gradually become an important tool in the field of mold manufacturing. The traditional mold manufacturing process faces problems such as long cycles, high costs, and limited designs, while 3D printing technology, with its advantages of rapid prototyping, complex structure manufacturing, and high material utilization, is gradually changing this situation. However, the application of 3D printing technology is not simply about equipment procurement, but requires a combination of specialized equipment, specialized materials, specialized processes, and rich technical experience to truly unleash its potential.

At this exchange meeting, ESU Laser showcased its "Overall Solution for Mold 3D Printing", aimed at helping mold companies fully master 3D printing technology, improve production efficiency, and reduce manufacturing costs. After comprehensively and truthfully understanding the user's needs and pain points, the professional team of Yisu Laser conducts a feasibility analysis of the overall solution for the user, including configuring mold 3D printing special equipment, special materials, special processes, supporting auxiliary equipment, production site planning, engineering and technical personnel training, and providing long-term operation and maintenance services for the user.

On site technical exchange meeting

We are not just a company that provides 3D printing processing services, but also a company that offers comprehensive solutions from equipment, materials, processes to services and training. ”ESU Laser Marketing Center General Manager Zhang Jun said at the meeting, "Yisu entered the mold industry in 2007 and started researching mold 3D printing technology in 2018. We focus on developing specialized equipment, materials, and processes, and are committed to helping mold companies transition from traditional manufacturing to intelligent manufacturing

Speech by Zhang Jun, General Manager of Marketing Center

The exchange meeting of ESU Laser is not only a technical demonstration, but also an important measure to promote the transformation of the mold industry. The popularization and application of 3D printing technology will greatly improve the efficiency and quality of mold manufacturing, and promote the development of the entire industry towards intelligence and digitization.