In the field of mold manufacturing, 3D printing technology has significantly improved cooling efficiency and product yield through its innovation in conformal waterway design. However, how to further save printing costs while utilizing the advantages of 3D printing is a focus of attention in the industry. Grafting printing technology, as a solution to this challenge, is being widely applied.

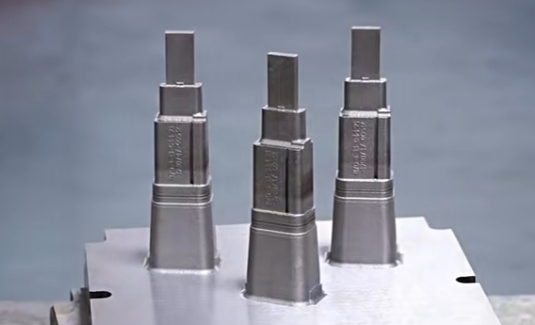

Grafting printing is a 3D printing process that cleverly combines the advantages of traditional processing methods and 3D printing technology, making it particularly suitable for the manufacturing of large, complex structured products. In this technology, a portion of the product is manufactured through traditional processing methods such as cutting and casting to ensure the strength and stability of the external structure; And the other part is completed through 3D printing to achieve fast and precise manufacturing of complex internal structures.

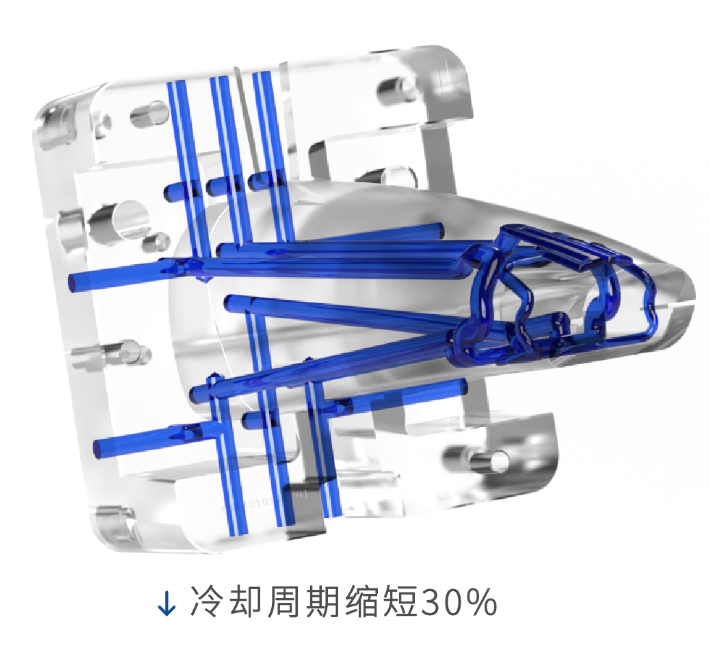

The application of grafting printing technology is particularly prominent in mold manufacturing. For the heat accumulation area in the mold, 3D printing technology can be used to design a conformal waterway to optimize the cooling effect; In areas with less heat accumulation, traditional waterway design can be used. This hybrid manufacturing method not only effectively improves the cooling efficiency of the mold, but also significantly reduces printing costs. Compared to full printing methods, cost savings can reach 2/3 or even more.

In addition, grafting printing technology has greatly improved production efficiency, shortened product launch time, and enhanced the market competitiveness of enterprises. At the same time, the technology produces products with better performance and longer service life, meeting the market's demand for high-quality products.

In summary, grafting printing technology has been widely applied in the field of metal 3D printing due to its high efficiency and economic advantages, and is an important driving force for the transformation and upgrading of the mold manufacturing industry.