With the continuous advancement of technology, 3D printing technology is gradually penetrating into various industries, especially demonstrating significant advantages in the field of mold manufacturing. Among them, 3D printing conformal waterway technology has been widely used in injection molds and is accelerating its expansion into the field of die-casting molds.

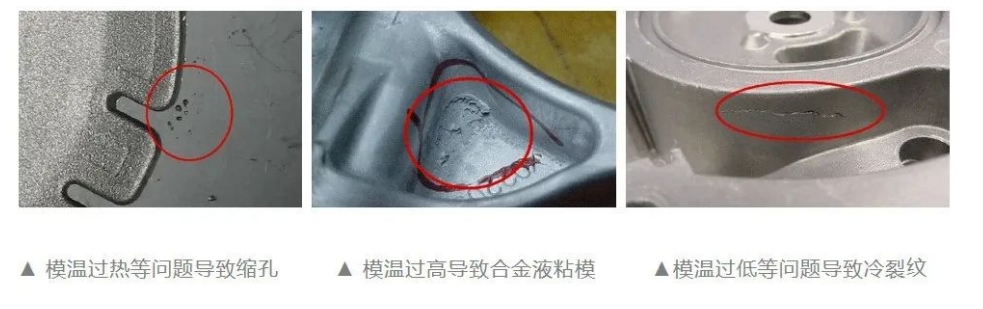

Although traditional CNC and other subtractive processes can produce straight cooling water channels, the force is insufficient when manufacturing complex shapes such as spiral shaped cooling water channels. In contrast, 3D printing technology has been widely used in injection molds due to its ability to form complex structures in one piece. It effectively controls mold temperature, improves product yield, shortens cooling time, enhances dimensional stability and surface smoothness, and promotes demolding. It is widely used in industries such as 3C, packaging, medical, automotive, and home appliances.

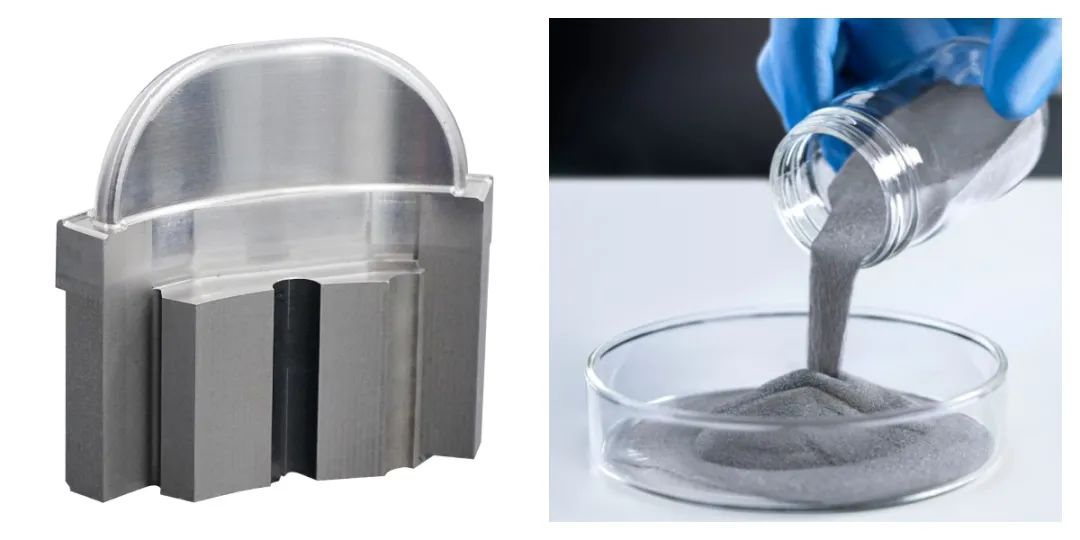

Die casting molds have higher requirements for 3D printing materials due to the more harsh working environment and higher working temperature. At present, the main types of die-casting 3D printing materials in the market are H13, such as DAC55, Dievar, W350, etc., but there are few materials that fully meet the needs of die-casting molds. In response to this challenge, Shanghai Yisu has launched EM213 hot work die steel powder through long-term research and development. This material exhibits excellent printing performance, toughness, thermal stability, thermal fatigue, and thermal conductivity, with an impact toughness (ISO V) of up to 35, making it highly suitable for die-casting molds. At present, EM213 has been successfully applied in the fields of automobile manufacturing, aerospace, shipbuilding, electrical appliances, etc., significantly promoting the adoption of 3D printing technology in these industries.

Looking ahead, with the acceleration of research and development of metal 3D printing materials, the emergence of more high-performance new materials will further broaden the application scope of 3D printing technology. The use of efficient conformal cooling water channels in die-casting molds will become a norm in the industry, bringing revolutionary changes to the manufacturing of die-casting molds.