From September 11th to 13th, the 22nd Chengdu Rubber, Plastic & Packaging Industry Exhibition was grandly held at Chengdu Century City New International Convention & Exhibition Center. As a leader in the mold 3D printing industry, Shanghai ESU Laser Technology Co., Ltd. (abbreviated as ESU Laser) made a wonderful appearance with its cutting-edge 3D printing technologies and innovative application achievements, attracting the attention of numerous industry professionals and becoming one of the focal points of the exhibition.

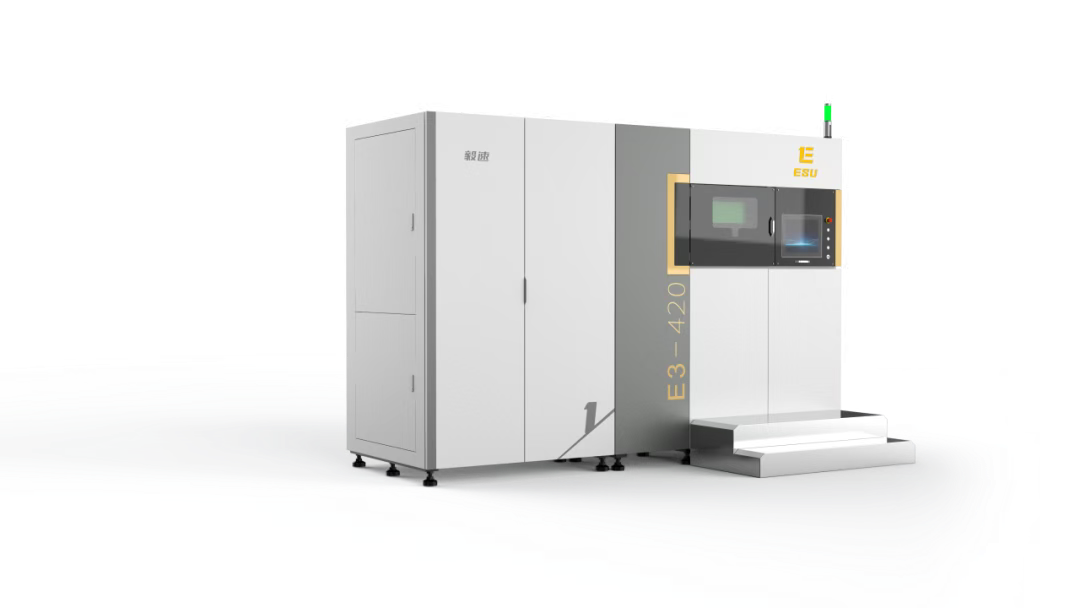

ESU 3rd-Generation Mold-Specific 3D Printing Machine Series E3

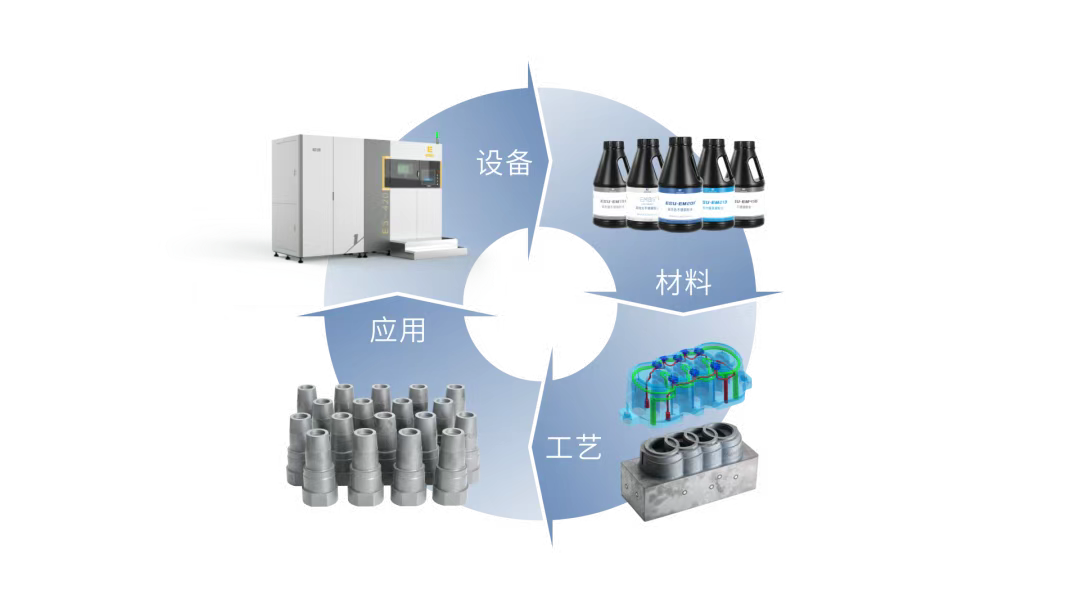

Equipment, materials, and processes do not exist independently; instead, they form a collaborative driving system featuring "hardware as the foundation – material adaptation – process empowerment". Specifically, the high efficiency and stability of equipment provide support for the implementation of processes; customized materials create conditions for the full release of equipment performance; and mature processes in turn promote the optimization and upgrading of equipment and materials. It is precisely the in-depth linkage and mutual empowerment among these three elements that ultimately achieve comprehensive breakthroughs in the efficiency, precision, and stability of mold 3D printing, injecting new impetus into the high-quality development of the mold industry.

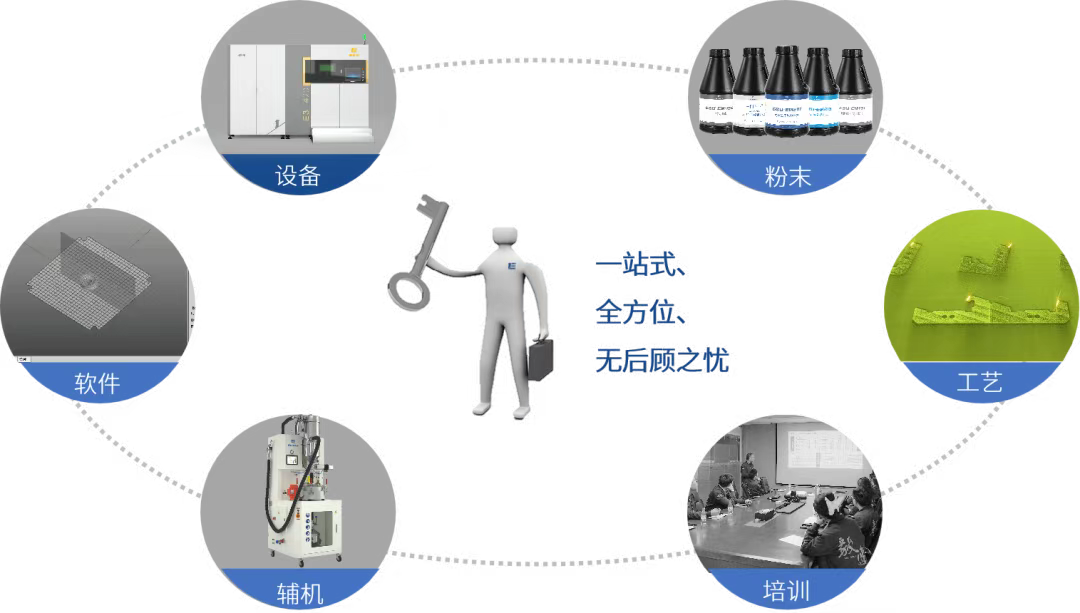

Based on the above-mentioned technology closed-loop consisting of mold-specific equipment, mold-specific materials, mold-specific processes, and mold application experience, ESU Laser is empowering Chinese mold enterprises with a comprehensive solution that "helps customers build and operate 3D printing centers". After conducting a comprehensive and in-depth investigation to understand customers' needs, pain points, and investment expectations, ESU Laser's professional team conducts a feasibility analysis of the overall solution for customers. This includes configuring mold-specific 3D printing equipment, dedicated materials, specialized processes, and supporting auxiliary machinery, followed by site planning and personnel training, and finally providing long-term operation and maintenance services.

Looking ahead, ESU Laser will continue to uphold the concept of "Making Manufacturing Easier and Faster" . Relying on advanced 3D printing technology, it will continuously explore innovative application scenarios, help more industries achieve the goals of quality improvement, cost reduction, and efficiency enhancement, and contribute more to promoting the transformation and upgrading of the manufacturing industry.